In the competitive world of food manufacturing, having access to the right resources is crucial for staying ahead of the game. Manufacturers need to stay informed about the latest trends, innovations, and technologies in the industry to produce high-quality products that meet consumer demands. In this article, we will discuss four essential resources that can help food manufacturers improve their processes and maintain a competitive edge in the market.

The Importance of Quality Fuel for Food Manufacturing

Efficient and reliable transportation is critical for food manufacturers because it ensures the timely delivery of ingredients and finished products. This calls for the use of high-quality fuel that enhances the performance of vehicles and keeps them running smoothly. A trusted fuel supplier in Alberta, for instance, can provide food manufacturers with the necessary fuel options to maintain a healthy transportation ecosystem.

Using the right type of fuel can help reduce overall transportation costs by improving fuel efficiency and reducing vehicle downtime. This means faster deliveries and a more streamlined supply chain for food manufacturers. Additionally, choosing an environmentally friendly fuel option can help support sustainability initiatives and reduce carbon footprint, which is an increasingly important consideration for modern consumers and retailers.

Working with a reliable fuel supplier also means receiving expert advice and support in selecting the right fuel for your operations. They can help you understand the compatibility of different fuel options with your existing vehicles, make recommendations based on your specific requirements, and even provide ongoing support through fuel management services. In conclusion, having a dependable fuel supply is vital for the smooth and efficient functioning of food manufacturing operations.

Innovative Ingredients for the Manufacturing Industry

Consumers today demand unique and innovative food products with enhanced flavors, textures, and nutritional profiles. To meet these requirements, manufacturers need access to a diverse range of high-quality ingredients. Find a resource that offers a vast selection of manufacturing industry ingredients. These ingredients can help manufacturers create new products or improve existing ones, allowing them to stay ahead of consumer trends and maintain a competitive edge.

Some of the industry ingredients available include fresh frozen culinary herbs, spice pastes, purées, and unique blends that can enhance the flavor, aroma, and visual appeal of food products. These ingredients can be customized to suit specific manufacturing processes and product formulations, making it easy for manufacturers to incorporate them into their operations.

Additionally, it is essential for manufacturers to work with ingredient suppliers who are transparent about their sourcing, processing, and safety practices. This ensures that the ingredients used in manufacturing processes meet the highest quality standards and comply with relevant safety regulations. Overall, incorporating innovative and high-quality ingredients is vital for manufacturers looking to develop unique and appealing food products that cater to evolving consumer preferences.

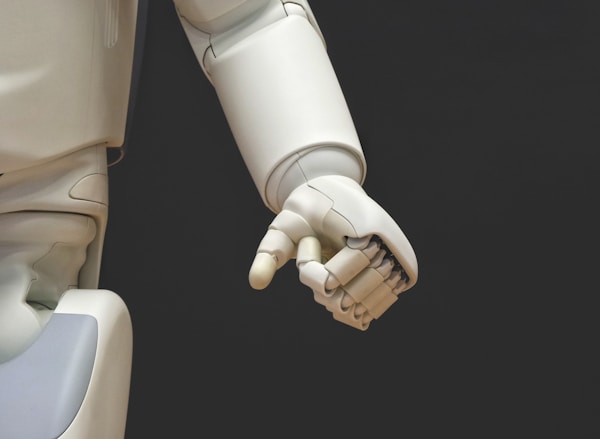

Investing in Automation and Robotics

As the food manufacturing industry continues to grow and evolve, automation and robotics have become increasingly important for maintaining efficiency, productivity, and competitiveness. By investing in these technologies, manufacturers can streamline their production processes, reduce labor costs, and minimize errors and waste. This ultimately results in higher-quality products, lower overheads, and greater customer satisfaction.

There are various types of automation and robotics solutions available for manufacturers, such as automated packaging systems, ingredient handling and processing equipment, and robotic palletizing systems. These solutions can be tailored to suit the specific needs of each manufacturing facility, allowing for a high degree of customization and flexibility in production processes.

Implementing automation and robotics in food manufacturing processes can also improve worker safety by reducing the need for manual handling and heavy lifting tasks. Additionally, these technologies can help manufacturers quickly adapt to changing market conditions and fluctuations in consumer demand by allowing for swift adjustments to production processes and output. Thus, embracing automation and robotics is essential for manufacturers looking to remain competitive in today’s fast-paced market.

Utilizing Data Analytics and Artificial Intelligence

Data analytics and artificial intelligence (AI) have become invaluable tools for modern manufacturers to optimize their operations and make more informed decisions. By collecting, analyzing, and leveraging data on production processes, waste levels, energy consumption, and more, manufacturers can identify patterns and trends that can help them improve efficiency and reduce costs.

AI-powered predictive maintenance systems can monitor equipment performance, detect potential issues before they become critical, and minimize downtime due to malfunctions. This not only ensures a more reliable production process but also extends the life of equipment and machinery, resulting in significant long-term cost savings.

Altogether, food manufacturers must leverage the essential resources discussed above to improve their operations and maintain a competitive edge in the market. By investing in quality fuel, incorporating innovative ingredients, embracing automation and robotics, and utilizing data analytics and AI, food manufacturers can enhance efficiency, reduce costs, and develop unique, high-quality products that cater to the evolving needs of consumers.